Pakistan Textile Exporters Association

پاکستان ٹیکسٹائل ایکسپورٹرز ایسوسی ایشن

A.B.EXPORTS (PVT) LTD

-

3D Knitting

3D knitting technology enables the creation of three-dimensional structures and shapes directly from the knitting machine, reducing waste and improving the fit and functionality of garments. Pakistan garment, Pakistan textile factories, Pakistan textile exporter, Made in Pakistan, futuristic Pakistan

3D Knitting Three-Dimensional Knitting Advanced Knitting Technology 3D Textile Manufacturing 3D Knitwear 3D Knitting Machines Innovative Knitting Solutions Seamless 3D Knitting 3D Knitted Structures Modern Knitting Techniques

-

Abrasion Resistance Testing

Using a Martindale Abrasion Tester to evaluate the fabric\'s resistance to wear and tear. Ensures the longevity of the fabric\'s surface.

Abrasion Resistance Testing, Abrasion resistance, Wear and tear, abrasion resistance, testing, textile, durability, wear resistance, fabric performance, surface damage, quality control, longevity. Pakistan textile industry, Futuristic Pakistan, Made in Pa

-

Air Jet Jacquard

Air jet jacquard refers to a type of weaving technology that combines air jet weaving with jacquard patterning. Here’s a breakdown: Air Jet Weaving: This is a modern method of weaving where yarn is inserted into the shed (the opening between the warp yarns) using compressed air. It\'s known for its high-speed production capabilities and is often used for weaving lightweight fabrics. Jacquard Patterning: Jacquard refers to a mechanism on a loom that allows for intricate patterns to be woven into the fabric. Unlike traditional looms where patterns are limited, jacquard looms can create highly detailed designs by controlling each warp thread individually. Combination: Air jet jacquard combines the speed and efficiency of air jet weaving with the design versatility of jacquard patterning. This means you can produce complex, patterned fabrics at high speeds, making it suitable for a wide range of applications including apparel, upholstery, and home textiles. In essence, air jet jacquard weaving technology enables the production of intricately patterned fabrics efficiently, meeting both aesthetic and functional requirements in textile manufacturing.

air jet, jacquard weaving, textile, intricate patterns, high-speed, efficient, fabric production, advanced technology., made in pakistan, tech used in pakistan textile

-

Air Jet Plain Loom

Air jet plain refers to a type of fabric produced using air jet weaving technology without any additional pattern or design created by jacquard mechanisms. Here\'s a brief description: Air Jet Weaving: This modern weaving method uses compressed air to insert the weft yarn across the warp yarns, forming the fabric. It\'s known for its high speed and efficiency in production. Plain Weave: The term \"plain\" in this context refers to the simplest and most common weave structure, where each weft thread passes alternately over and under each warp thread. This creates a straightforward, uniform fabric surface without any elaborate patterns or textures. Combination: When air jet weaving is used to produce plain weave fabrics, the result is often lightweight, durable, and suitable for a wide range of applications including apparel, household textiles, and industrial fabrics. In summary, air jet plain fabrics are characterized by their simplicity and versatility, made possible by the combination of air jet weaving technology and the plain weave structure.

air jet, plain weave, textile, high-speed, efficient, fabric production, precision, modern technology.

-

Automated Inspection Systems

Automated Inspection Systems are advanced technologies used in manufacturing and production processes to ensure quality control and detect defects. These systems utilize machine vision, sensors, and artificial intelligence to automatically inspect products and components in real-time, providing accurate and consistent quality assurance. Automated Inspection Systems enhance production efficiency, reduce human error, and improve overall product quality by identifying and addressing defects early in the manufacturing process. They are widely used in various industries, including automotive, electronics, pharmaceuticals, and food processing, to maintain high standards of quality and reliability.

Automated Inspection Systems, quality control, inspection technology, automated quality assurance, industrial automation, defect detection, machine vision, automated testing, production line inspection, manufacturing efficiency, non-destructive testing, P

-

Automatic Cutting Machine

Machines used for precise cutting of fabric into various shapes and sizes. They improve cutting efficiency and accuracy, reducing fabric waste.

Automatic cutting Machine, Automatic cutting, Precision cutting, automatic cutting, textile, cutting machine, precision, high-speed, fabric cutting, automated, efficiency, accuracy, industrial, Gerber Technology, Bullmer, Kuris, Eastman, Zünd, Pakistan ga

-

Brushing / Raising Finish

Brushing or raising finish is a textile finishing process used to create a softer and warmer fabric surface. Here’s an explanation of each process: Brushing: Process: Brushing involves passing the fabric over rapidly rotating brushes. These brushes have fine wire bristles that gently lift the surface fibers of the fabric. Purpose: The brushing process helps to create a soft, fuzzy texture on the fabric surface by raising the nap (short fibers) of the yarns. This enhances the fabric’s warmth and comfort, making it suitable for cold weather clothing and bedding. Raising: Process: Raising, also known as napping, is similar to brushing but typically involves passing the fabric over cylinders covered with metal teeth or emery fillets. Purpose: This process raises the fibers on the fabric’s surface, creating a soft and plush texture. Raising is often used to produce fabrics like flannel or fleece, which are known for their warmth and insulating properties. Combined Effect: Both brushing and raising processes improve the fabric’s hand feel (softness) and increase its thermal insulation properties. Fabrics treated with brushing or raising finish are comfortable to wear and provide additional warmth, making them popular choices for winter garments, blankets, and other cold-weather textiles.

brushing, raising finish, textile, fabric texture, softening, surface enhancement, high-quality, finish process, Pakistan garment, Pakistan textile factories, Pakistan textile exporter

-

Chemical Residue Testing

Checking for harmful chemicals and residues on fabrics. Ensures that fabrics are safe and non-toxic for consumers.

Chemical Residue Testing, Chemical Residue Testing,Chemical residue, Fabric safety, chemical residue, testing, safety, quality control, textile, analysis, contaminants, compliance, certification, Pakistan industry, made in Pakistan, Pakistan textile indus

-

Circular Knitting Machines

Machines that produce fabrics in a circular or tubular form. Ideal for making seamless garments like T-shirts, underwear, and socks. They come in various gauges and diameters to produce different fabric textures and weights

Circular knitting, Tubular fabric, circular knitting, textile, knitting machines, continuous fabric production, high-speed, versatile, efficient, seamless, automated.

-

Color Fastness Testing

Testing the resistance of fabric colors to washing and fading under light exposure. Ensures that colors remain vibrant and do not bleed.

Color Fastness Testing, Color fastness, Wash fastness, Light fastness, color fastness, testing, textile, dye stability, color retention, washing resistance, light resistance, quality control, fabric performance. Pakistan garment, Pakistan textile factorie

-

Coverstitch Machines

Machines used for hemming and decorative stitching. They produce durable and flexible seams, suitable for stretchy fabrics

Coverstitch, Hemming, Decorative stitching, coverstitch, sewing machines, textile, stitching, seam finishing, durability, high-speed, professional, versatile.

-

Digital Printing

Machines used for high-quality, detailed prints on fabrics. They allow for customization and are suitable for small to medium production runs.

Digital Printing, Digital printing, High-quality prints, digital printing, textile, fabric printing, high-resolution, customized designs, efficient, color accuracy, modern technology , Pakistan garment, Pakistan textile factories, Pakistan textile exporte

-

Drying Setup-Tumble Dryer

A tumble dryer is a household or industrial appliance used to dry clothes and fabrics quickly and efficiently. Here’s a description of its setup and operation: Design and Structure: Drum: The core component is a rotating drum where clothes are placed for drying. This drum is perforated to allow heated air to circulate through the load. Heating Element: Typically located inside or near the drum, the heating element generates hot air to speed up the drying process. Air Circulation: A fan or blower circulates heated air through the drum, ensuring even drying of the clothes. Operation: Loading: Clothes are loaded into the drum through a front-loading or top-loading door. Settings: Users can select drying settings based on fabric type and desired dryness level (e.g., delicate, regular, high heat). Start: After selecting settings and loading the drum, the dryer is started. The drum rotates, and heated air is circulated through the clothes. Monitoring: Some dryers include sensors to detect moisture levels in the clothes, automatically adjusting drying times to prevent over-drying. Completion: Once the drying cycle is complete, the dryer may signal with a buzzer or indicator light. Safety Features: Thermostat: Prevents overheating by regulating the dryer’s temperature. Lint Filter: Collects lint and debris from clothes during drying to maintain airflow and prevent fire hazards. Cool Down Cycle: Allows clothes to cool gradually at the end of the cycle, reducing wrinkles. Types: Household Dryers: Typically electrically powered and designed for home use, available in various sizes. Commercial/Industrial Dryers: Larger capacity units used in laundromats, hotels, and textile industries for high-volume drying. Overall, tumble dryers offer a convenient and efficient way to dry clothes, providing users with dry, wrinkle-free garments in a relatively short amount of time compared to air drying.

tumble dryer, drying setup, textile, efficient, high-capacity, automated, fabric care, quick drying, Pakistan textile manufacturers, Pakistan factories

-

Dyeing Setup-Continuous Dyeing

Continuous dyeing is a method used in textile industries to dye fabrics in a continuous process, rather than batch-wise. Here’s a description of its setup and operation: Setup: Fabric Feeding: The process begins with continuous feeding of fabric into the dyeing machine from a roll or creel. Preparation: Fabrics may undergo preparation steps such as desizing, scouring, and bleaching to remove impurities and enhance dye absorption. Dye Liquor Preparation: Dyes are prepared in a solution suitable for continuous application, often with additives to control pH, leveling agents, and other chemicals to enhance dye uptake and uniformity. Operation: Dye Application: Fabrics are passed through a series of dyeing tanks or chambers where they are immersed in the dye liquor. Various methods can be employed for dye application: Pad Dyeing: Fabrics are padded through dye baths, where they absorb dye before passing through squeezing rollers to control the dye uptake. Spray Dyeing: Dye liquor is sprayed onto the fabric as it moves through the dyeing machine. Foam Dyeing: Dye is applied in the form of foam to enhance dye penetration and reduce water consumption. Steaming or Fixation: After dye application, fabrics may undergo steaming or heat setting to fix the dye permanently. Washing and Finishing: Finally, fabrics are washed to remove excess dye and chemicals, followed by finishing processes such as drying, calendaring, and inspection. Advantages: Efficiency: Continuous dyeing allows for high-speed production with minimal downtime between batches. Consistency: Ensures uniform dye penetration and color matching across large fabric batches. Economical: Reduces water and chemical consumption compared to batch dyeing methods. Versatility: Suitable for a wide range of fabrics including cotton, polyester, blends, and technical textiles. Applications: Continuous dyeing is widely used in industries producing apparel fabrics, home textiles, automotive textiles, and technical textiles where consistent color and fast production are essential. Overall, continuous dyeing setups are designed to optimize efficiency and quality in textile dyeing processes, meeting the demands of modern manufacturing for fast, consistent, and economically viable production of dyed fabrics.

Dyeing Setup, Continuous Dyeing, Dyeing, Fabric Dyeing, continuous dyeing, dyeing setup, textile, high-efficiency, color consistency, automated, industrial, fabric processing, textile manufacturers Pakistan, Pakistan Factory,

-

Finishing Machines

Machines used for finishing fabrics to improve their texture, appearance, and physical properties. Stenters, compactors, and calendaring machines are commonly used.

Fabric finishing, Stenter, Compactor, Calendaring, finishing machines, textile, fabric treatment, quality enhancement, smoothing, surface finishing, automated, precision, efficiency.

-

Flat Knitting Machines

Advanced knitting machines are used for high-speed and precise knitting of hosiery and knitwear. These machines can produce intricate patterns and designs efficiently.

Computerized Knitting Machines Advanced Knitting Technology Precision Knitting High-Speed Knitting Machines Automated Knitting Systems Textile Machinery Modern Knitting Equipment Knitting Pattern Automation Industrial Knitting Technology Efficient Knittin

-

Heat Press Machines

Machines used for applying heat transfer designs onto fabrics. Ideal for adding logos, labels, and decorative elements.

Heat Press Machines,Heat press, Heat transfer designs, heat press, textile, fabric pressing, temperature control, high-pressure, transfer printing, automated, efficient, precision, customization. Pakistan textile, made in Pakistan, futuristic Pakistan

-

Jet Dyeing Machine

Machines used for dyeing knitted fabrics with uniform color distribution. Suitable for a variety of fabric types and dye classes

jet dyeing, textile, dyeing machine, high-speed, efficient, fabric coloration, automated, precision, versatility. Pakistan Industry, Pakistan Textile industry, made in Pakistan, Futuristic Pakistan

-

Laser Cutting Machines

Machines used for detailed and accurate cutting, often for complex designs. They provide clean edges and can cut through multiple layers of fabric.

Laser Cutting Machines, Laser cutting, Detailed cutting, laser cutting, textile, cutting machines, high-precision, automated, efficient, intricate designs, accuracy, industrial, non-contact. made in Pakistan, Pakistan textile industry, futuristic Pakista

-

Moisture Management Testing

Measuring the fabric\'s ability to wick moisture away from the skin. Ensures comfort and dryness during wear.

Moisture Management Testing, Moisture management, Fabric wicking, moisture management, testing, textile, absorbency, wicking properties, fabric performance, comfort, analysis, water resistance. made in Pakistan, Pakistan textile industry, tech in Pakistan

-

Moisture-Wicking and Antimicrobial Fabrics

Innovations in textile engineering have led to the development of fabrics that wick moisture away from the body and have antimicrobial properties, enhancing the comfort and hygiene of hosiery products.

Antimicrobial Fabrics Performance Textiles Sweat-Wicking Materials Hygienic Textiles Breathable Fabrics Anti-Odor Fabrics Quick-Dry Fabrics Activewear Materials High-Performance Textiles Moisture Management Antibacterial Fabrics moisture-wicking, antimicr

-

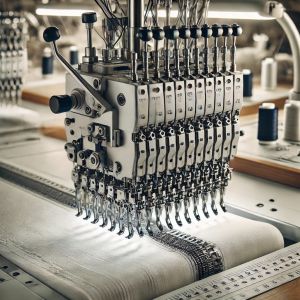

Multi-Needle Embroidery Machines

Machines used for creating intricate embroidery designs on garments and fabrics. They can handle multiple colors and complex patterns efficiently

Multi-Needle Embroidery Machines, Embroidery, Multi-needle, multi-needle embroidery, textile, embroidery machines, high-speed, precision stitching, automated, versatile, detailed designs, professional.

-

_Machines.webp)

Overlock (Serger) Machines

Machines used for sewing seams, hemming, and edging fabrics. They trim excess fabric while sewing, providing a clean finish and preventing fraying.

Overlock, Serger, Seam finishing, overlock, serger, sewing machines, textile, edge finishing, seam construction, high-speed, precision, versatile, professional.

-

Pad Dyeing Machines

Machines used for dyeing fabrics continuously. They ensure consistent color application and are efficient for large-scale production.

pad dyeing, textile, dyeing machines, efficient, high-capacity, color application, fabric treatment, automation, precision.

-

pH Testing

Ensuring the fabric\'s pH level is safe for skin contact. Prevents irritation and allergic reactions.

pH Testing, pH testing, Skin safety, pH testing, acidity, alkalinity, textile, quality control, analysis, fabric treatment, chemical balance, measurement, made in Pakistan, Pakistan textile industry,

-

Screen Printing Machines

Machines used for applying designs and patterns onto fabrics. Suitable for large volumes and allows for vibrant, durable prints.

Screen Printing Machines, Screen printing, Fabric printing, screen printing, textile, printing machines, high-resolution, color application, fabric decoration, efficient, automated, versatile, Pakistan garment, Pakistan textile factories, Pakistan textile

-

Seam Strength Testing

Assessing the durability of seams under stress. Ensures that seams do not easily break or come apart.

Seam Strength Testing, Seam strength, Durability testing, seam strength, testing, textile, durability, fabric integrity, load resistance, quality control, performance, stress analysis,made in Pakistan, Pakistan textile industry, tech in Pakistan,

-

Shrinkage Testing

Shrinkage testing is a fundamental process used to evaluate the dimensional stability of textiles and garments. It involves subjecting fabric or garments to controlled conditions, typically washing and drying cycles, to simulate real-world use. The testing measures the extent to which fabrics or garments shrink or change dimensions after laundering, providing valuable insights into their quality and performance. Shrinkage testing helps manufacturers ensure that products meet desired size specifications, maintain shape consistency, and adhere to industry standards for dimensional stability. It is crucial for quality control in the textile and clothing industries, ensuring customer satisfaction and product durability.

Shrinkage Testing, fabric testing, textile testing, shrinkage analysis, textile properties, fabric shrinkage, dimensional stability, garment testing, textile quality control, fabric performance, textile standards, fabric shrinkage testing, clothing indust

-

Smart Textiles

Integration of technology in textiles for features like temperature regulation and health monitoring, enhancing functionality of knitwear.

Smart Textiles Temperature Regulation Fabrics Health Monitoring Textiles Functional Knitwear Wearable Technology Intelligent Fabrics Smart Clothing Sensor-Embedded Textiles Advanced Knitwear Tech-Enhanced Fabrics E-Textiles Smart Fabric Technology, Pakist

-

Steam Presses

Machines used for removing wrinkles and giving a crisp finish to garments. They use steam and pressure to achieve a professional look.

Steam Presses,Steam press, Wrinkle removal, steam presses, textile, fabric finishing, wrinkle removal, high-temperature steam, professional quality, efficient, smoothening, automated. Pakistan textile industry, futuristic Pakistan, Pakistan industry

-

Stretch and Recovery Testing

Evaluating the elasticity and recovery of fabrics. Ensures that fabrics can stretch and return to their original shape without deformation.

Stretch and Recovery Testing, Stretch testing, Fabric elasticity, stretch testing, recovery testing, textile, fabric elasticity, durability, deformation, performance, quality control, flexibility.

-

Sustainable and Eco-Friendly Materials

Use of eco-friendly materials like organic cotton, bamboo, and recycled fibers, reducing environmental impact and appealing to eco-conscious consumers.

Sustainable Materials Eco-Friendly Fibers Green Textiles Organic Cotton Recycled Fabrics Biodegradable Textiles Eco-Conscious Materials Renewable Fibers Sustainable Fashion Environmentally Friendly Textiles Eco-Friendly Clothing Sustainable Manufacturing

-

Tear Strength Testing

Measuring the resistance of fabric to tearing. Ensures that fabrics do not easily rip or tear under tension.

Tear Strength Testing, : Tear strength, Fabric durability, tear strength, testing, textile, fabric durability, resistance, quality control, stress, performance, fabric integrity. Pakistan garment, Pakistan textile factories, Pakistan textile exporter, Mad

-

Visual Inspection

: Inspecting fabrics for defects such as holes, stains, and color variations. This process ensures that only high-quality fabrics are used in production.

Visual inspection, Fabric defects, visual inspection, textile, quality control, defect detection, fabric evaluation, manual checking, accuracy, detail-oriented, consistency, AQL (Acceptable Quality Level) standards, ISO 2859-1 (Sampling Procedures), ASTM

-

Warping Machine

A warping machine is an essential piece of equipment in the textile industry used primarily in the preparation of warp yarns for weaving. Here’s a detailed description of its setup and operation: Purpose: Warp Preparation: The primary function of a warping machine is to create a warp beam, which holds parallel yarns (warp yarns) under tension in preparation for weaving. Setup and Components: Creel: Yarn cones or packages are mounted on a creel, which holds multiple yarn ends (typically one end per warp yarn) and allows them to unwind freely. Tensioning Device: Yarns pass through tensioning devices to maintain consistent tension as they are wound onto the warp beam. Warping Drum or Sectional Warping System: The core component where yarns are wound onto the warp beam. Warping Drum: Used in direct warping, where yarns are wound directly onto the beam in a continuous process. Sectional Warping System: Used in sectional warping, where yarns are wound onto several smaller beams (sections) which are later combined to form the full warp beam. Yarn Guide: Guides or eyelets ensure proper alignment and tension of yarns as they move from the creel to the warping drum. Warp Stop Motion: Detects yarn breaks and stops the machine to prevent issues during the warping process. Control Panel: Allows operators to set parameters such as warp length, yarn tension, and speed. Operation: Loading: Yarn ends are threaded from the creel through tensioning devices and yarn guides to the warping drum. Warping Process: As the drum rotates, yarns are wound onto the warp beam under controlled tension. The speed and tension are adjusted to ensure uniform winding and proper alignment of yarns. Inspection: Operators monitor the process for any yarn breaks or irregularities, using the warp stop motion to halt the machine if necessary. Beam Build-Up: Depending on the type of warping (direct or sectional), the full warp beam is built up with yarn layers wound in a precise pattern. Beam Removal: Once the desired length of warp yarn is wound, the warp beam is removed from the machine for further processing or directly transferred to a weaving machine. Types: Direct Warping Machine: Yarns are wound directly onto the warp beam in a continuous process. Sectional Warping Machine: Yarns are wound onto smaller beams (sections) which are later combined to form the full warp beam. Warping machines play a crucial role in ensuring the efficiency and quality of the weaving process by preparing warp yarns in a controlled and systematic manner. They are essential in both small-scale and large-scale textile production for various types of fabrics.

warping machine, textile, weaving, yarn preparation, efficient, high-capacity, precision, industrial, textile manufacturers

Name: Mr.Muhammad Ahmed

Address: Lasani Pulli, Near Khayban Gardens,Sargodha Road

Website: https://www.ab.com.pk

Profile URL: https://ptea.petrolsolutions.com/abexports-pvt-ltd

Certifications:

.jpg)

.jpg)

.jpg)

.jpg)